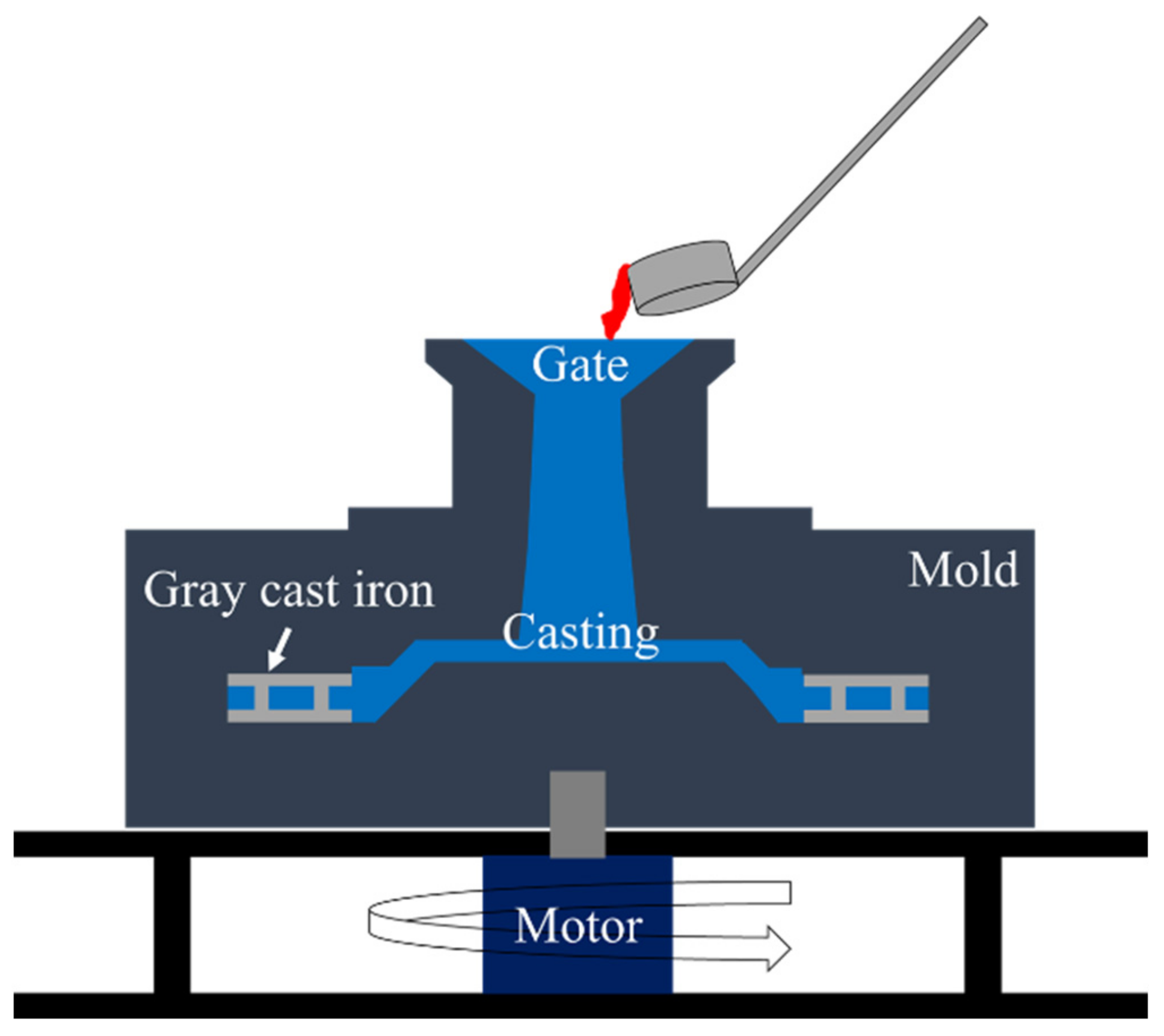

Figure 4 depicts a design of a centrifugal casting machine for the fabrication of pistons by Seabra et al. The vacuum centrifugal casting method of casting jewelry is mainly used to cast jewelries with a high melting temperature like we have in palladium platinum and stainless steel.

Pro E 3d Model Of Centrifugal Casting Machine Download Scientific Diagram

In this method the mould is rotated in a vertically axis.

. During the process in centrifugal casting along the vertical axis. Circuitreversible time can be set any time. Capable of handling up to 100000 lbs 45359 kgs of dynamic loads with casting sizes up to 120 3M Diameter.

All process steps are conducted simultaneously. Typically a horizontal designed machine is used to produce a thin cylinder while vertically mounted machines for producing rings or similar products. Fully automated hot mold centrifugal casting machine.

Centrifugal casting consists of a number of processes in which the centrifugal force set up by the rotation of a part of the casting is utilized to shape the casting fill the mould and help solidify and strengthen the metal Pavlovic et al 2009. With 45 years of experience in the Machine Design Manufacture Equipment Installation and Personnel training for Vertical and Horizontal centrifugal casting machines. Where the rotational speed.

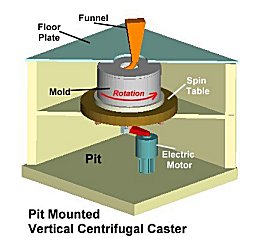

A wax mode a wax mode can be any combustible material is. With 45 years of experience in the Machine Design Manufacture Equipment Installation and Personnel training for Vertical and Horizontal centrifugal casting machines. A typical vertical centrifugal casting machine is shown.

2 Vertical centrifugal casting This type of casting is followed for cylinder type bodies having ring geometry. This paper is organized as follows. The molds are revolved clockwise inside the machine to each process step.

4Elborate design and cinvenient operation 5When polishing chamber is took out of machinetumber will stop automatically to save power. Design and selection of the systems components was performed accordingly. The operation of the.

The design and fabrication of a centrifugal casting mach ine was successfully carried out. Gibsons customers can then realistically visualise all component parts prior to machine manufacture. Our state-of-the-art equipment generates pressures up to 60 times the force of gravity to segregate and remove impurities and other unwanted elements from our products.

Here The machine has four rollers and all of them are being used. Vertical centrifugal casting machine 12 41. A centrifugal casting machine in a safety ring with the burned out flask in place white cylinder eoeeeooeoeecasting machine with the casting flask A in position for melting metal prior to casting.

The maximum temperature for melting is usually 2000 degree celsius. All of our gear blanks are machined with high dimensional accuracy. Vertical Centrifugal Casting Machine.

Machine was based on the principle of. The casted products diameter ranged from 50mm to 2000mm with length ranged from 50mm to 2000mm. 1000 liners soil drain pipes up to 280 pcsh of DN1003000 acc.

Then in section 2 the conceptual design developed for the centrifugal casting machine for pistons is presented. Animation showing what happens during the vertical centrifugal casting processTo learn more about the centrifugal casting process visit us at httpswwwm. High g-forces applied to the molten metal in the.

Tulsa Centrifugal Casting Machines LLC founded by the leading centrifugal casting specialists in the USA. Two rollers are at the bottom and two are at the top of the system. With 40 years of experience in the Machine Design Manufacture Equipment Installation and Personnel training for Vertical and Horizontal centrifugal casting machines.

Tulsa Centrifugal Casting Machines LLC founded by the leading centrifugal casting specialists in the USA. An automotive piston was produced and rated for mechanical properties after it was. This video shows what happens during the centrifugal casting process.

There is a difference between vertical centrifugal casting and horizontal centrifugal casting. Cylinder liners up to 90 pipesh comes up to appr. The Cores are used to create hollow sections or cavities in a casting.

The work has been completed with design and fabricated of a low cost horizontal and vertical centrifugal casting machine with the main accessories for producing a. LS-32 vertical centrifugal grinding mill machine. To DIN EN 877 TAILOR-MADE Solutions for.

V10 thru V100K Series. Please visit the following links for more information or email our sales team salesgibsoncentritechcouk. The vertical centrifugal casting machines adopt fully automated systems utilizing.

Centrifugal casting machines for ferrous and non-ferrous castings. Horizontal centrifugal casting preferred for the tube geometry. Isometric view of the to be used in centrifugal casting technique 18 42.

These heavy duty Vertical Axis machines are the workhorse of the centrifugal casting industry in producing a variety of ferrous and non-ferrous castings in a variety of shapes and sizes. The vertical centrifugal casting machines adopt fully automated systems utilizing programmable logic controllers PLC with functions of automatic pouring automatic mold coating automatic mold inner wall cleaning and automatic extraction. The white disc in the foreground B is the hard asbestos steam head.

Yihui Casting Technology. Vertical Centrifugal Casting Machines Further Information. Our machine designs produce.

Our floor and pit mounted vertical centrifugal casting machines are used to produce the duplexed mill rolls cylinder liners bronze or copper alloy tubes brake drums discs bottle molds flywheels and stainless grates etc. Section 1 provides a brief overview of the thematic literature related to the state of the art of centrifugal casting. Horizontal centrifugal casting machine 12 23.

Centrifugal casting machine is needed in the mineral processing industry to reduce waste and increase mineral separation efficiency. The mold can itself be rotated horizontally or vertically depending upon the design requirements. Our machine designs produce castings in both ferrous and non-ferrous material from a few pounds.

The centrifugal casting cast only symmetrical shapes therefore Limited design can be cast from. What is vertical centrifugal casting. 11 Vacuum Centrifugal Casting Method.

Vertical Centrifugal Casting Machine Manufacturer Gibson Centri Tech Ltd. This allows design reviews to be presented in an easy to understand format allowing a rapid and inexpensive development process. Our engineers complete 3D designs of every customers centrifugal casting machine before any metal is cut.

Our vertical centrifugal casting techniques produce gear blanks with high purity density and durability. Horizontal centrifugal casting machine is shown in Fig. Initial rotor head design a showed the hole for mould fitting and b showed the hole to be fitted with the motor shaft.

The work has been completed with design and fabricated of a low cost horizontal and vertical centrifugal casting machine with the main accessories for producing a. 3Electrical parts are made by imported material to extend the file of machine.

Schematic Of The Vertical Centrifugal Casting Machine Huang Et Al 16 Download Scientific Diagram

Tulsa Centrifugal Casting Machines Vertical Machines

Pdf Design And Development Of A Centrifugal Casting Machine For Pistons Production Semantic Scholar

Vertical Centrifugal Casting Machine Download Scientific Diagram

Constructive Scheme Of A Centrifugal Casting Machine With A Vertical Download Scientific Diagram

Tulsa Centrifugal Casting Machines Vertical Machines

Applied Sciences Free Full Text Effects Of Heat Treatment On The Microstructure And Hardness Of A356 Alsi7mg0 3 Manufactured By Vertical Centrifugal Casting

0 comments

Post a Comment